BOX OVENS

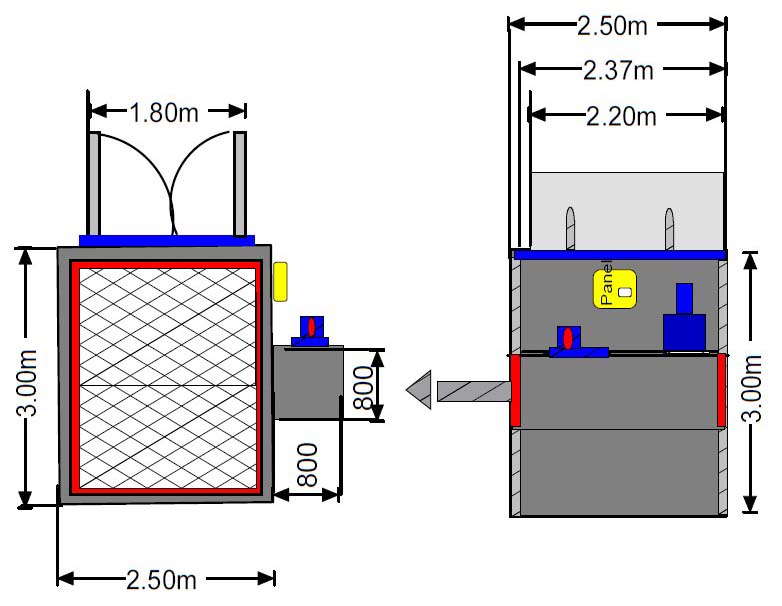

All our box ovens come in varying sizes generally 2 metres cube internal and upwards through a combination of sizes up to and including 8 meters x 3 meters x 2.9 meters high

Larger sizes, please ask for details.

BOX OVENS

CONSTRUCTION: WALLS

The main body of all our ovens are manufactured from in house built insulated wall panels.

Constructed from Galvanised sheet (unless requested otherwise)

Each panel is made up of two inverted trays, packed with High Density Rockwool 100mm – 130mm thick, the trays are then secured together, sandwiching the insulation tightly between them, the trays are secured together with a minimal of metal strips that leaves a heat break (Gap) between the inner and outer skins of the panel to reduce heat transfer from within the oven.

CONSTRUCTION: ROOF

Roof panels are built to the same thickness as the wall panels, with the inner skin of the panel being punched with a series of holes throughout, this is then covered with 2 thou thick reinforced foil, the insulated slab is the packed into the tray and a further layer of foil is then fitted to finish the panel, these are designed as explosion relief panels that are fitted to meet with regulations.

CONSTRUCTION: DOORS

The main structure of the door is manufactured from hollow box section frame that allows a secure fixing for all the door furniture., then packed with the insulated slab a per all the main oven panels and skinned with galvanised sheet to finish

CONSTRUCTION: BURNER BOX

Manufactured from M/S Sheet cut and built around support steels and fully welded throughout to provide a robust “Box” that can withstand the heat being generated by the burner

The box is then clad again in the same insulation as the walls and roof and then fully encapsulated in a galvanised sheet covering.

The burner box will house the circulating high temperature plug fan or fans (Subject to oven size one or two delivery fans will be incorporated into the build) and the main Gas Burner

CONSTRUCTION: AIR CIRCUALTION

Hot air is fed from the burner box (either mounted to the oven roof or floor mounted beside an oven back wall) through delivery ducts that are fitted low level from front to rear of the internal wall of the oven, one side with single fan delivery and both sides on twin fan delivery.

The incoming hot air is adjustable via a series of slots along the length of the delivery ducts.

The air in turn is drawn from a further adjustable vent fitted high level that feeds directly back into the burner box and across the face of the burner to maintain the temperature before the air recycles back through the high temperature fan or fans into the distribution ducts

CONSTRUCTION: CONTROLS

Controls will be built into a fully enclosed control panel comprising of:

- Main Electricity supply isolating switch; this needs to be “OFF” position before panel can be opened.

- All Contactors and overload to each fan assembly

- All burner controls

- Interlocking A/F switch circuitry that blocks live supply to burner if fans not functioning

- Process timer to enable operator to set required time for cure and shut burner down when timed out

- Shut down timers that allows the fans to run on after main oven shut down to avoid stagnant heat damage to fans and burner box, these are generally pre-set on oven commissioning by the commissioning engineer.

- Digital Temperature display and Temperature setting

- Digital display high temperature set, to avoid overheat in the event of main thermostat malfunction

- Remote alarm for “Lockout” of burner

The smaller range of Ovens are when possible pre built whilst larger units are palletised and assembled on site

Ovens available in Natural Gas and LPG.

Commissioning of all our ovens will be carried out by Registered “Gas Safe Engineers”

We can change design of certain parts in our manufacture that can save on overall finished price, this is all down to the quality of the product we are manufacturing and your own end preference.

WANTED NOW

Second hand Powder coating equipment

Second Hand Powder coating ovens

Complete Used Powder coating systems

Ovens. Booths . Conveyors .

Pre Treatment :

Powder Reclaim systems

Alloy Wheel Refinishing Systems

We are always looking for good used equipment customers awaiting

Please Note : We also manufacture and Install New Powder Coating systems