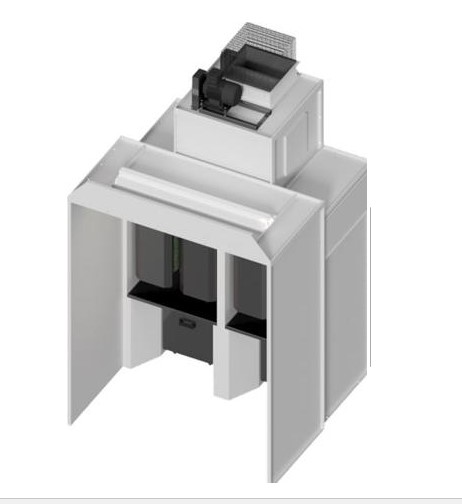

CARTRIDGE BOOTH – SPECIFICATION

- INTERNAL WORKING WIDTH – 2,000 MM

- INTERNAL WORKING HEIGHT – 2,500 MM

- AIRFLOW-3.1 WS

- AIR VELOCITY – 0.5 MIS AVERAGE

- POWER – 3 KW

ELECTRIC -415!3150 VOLTAGE! PHASE! HERTZ

AIR – 4-6 BAR

FILTERS – 8 OFF TA1 FILTER ELEMENTS. CARBON IMPREGNATED ANTI-STATIC.

- BINS – 2 OFF REMOVABLE COLLECTION HOPPER BINS

Cartridge booths are manufactured in 1 . 2 and 3 meter modules and can be joined together to form the length of extraction area you require

CARTRIDGE BOOTH – DESCRIPTION

- THE AWR POWDER AND EXTRACTION CARTRIDGE BOOTH COMBINES TWO FUNCTIONS IN ONE INTEGRATED MODULE. IT COMPRISES A SPRAY CANOPY DESIGNED FOR THE APPLICATION OF DRY POWDER PAINTS ATTACHED TO AN EXTRACTION AND CLEANING MODULE WITH HOPPER RECOVERY. THE TOTAL SYSTEM PROVIDES A SAFE, CLEAN AND EFFICIENT WORKING ENVIRONMENT WITHOUT THE NEED FOR EXTERNAL DUST EXTRACTION IT CAN ALSO BE ADAPTED TO OTHER DRY COATING AND SURFACE FINISHING APPLICATIONS.

SINGLE MODULE CARTRIDGE BOOTH

- AWR POWDER BOOTHS ARE AVAILABLE IN BOTH SINGLE AND DOUBLE MODULE SIZES. THEY CAN BE GROUPED UP TO 4 UNITS IN WIDTH AND CAN ALSO BE CUSTOMIZED TO LARGER SIZES IF REQUIRED.

PULSE AIR RECEIVERS

- SINGLE OR TWIN MODULE PULSE AIR RECEIVERS ARE LOCATED EXTERNALLY AT THE BACK OF THE CONTAINER EXTERNALLY WITH EXTENDED PIPES TO ASSIST THIS INSTALLATION METHOD. TO EXTRACT THE WASTE POWDER AND CLEAN THE FILTERS

CONTROL PANEL

- THERE IS A SINGLE CONTROL PANEL FOR THE SPRAY BOOTH AND AIR PULSE SYSTEM. IT IS EASY TO OPERATE AND MAINTAIN.

- THIS SYSTEM WILL HAVE A TIMED PULSE WHILST SPRAYING AND AN INVERTER DRIVEN MOTOR WHICH WILL REDUCE THE SPEED OF THE FAN IN CLEAN DOWN MODE, TO ASSIST CLEANING OF THE FILTERS.

FILTER ELEMENTS

- AIR IS DRAWN IN EVENLY ACROSS THE FACE AREA AND TOWARDS THE FILTER SECTION IN THE BACK OF THE ENCLOSURE. OVERSPRAY POWDER IS DRAWN TOWARDS THE FILTERS, WHERE REVERSE PULSE CLEANING REMOVES THE POWDERS ON DEMAND

BAFFLE SYSTEM

- A BAFFLE SYSTEM REDUCES PRESSURE ACROSS THE FILTERS AT THE MOMENT OF PULSE CLEANING TO MAXIMISE THE RECOVERY OF THE POWDERS FROM THE FILTERS TO THE COLLECTION HOPPERS.

WANTED NOW

Second hand Powder coating equipment

Second Hand Powder coating ovens

Complete Used Powder coating systems

Ovens. Booths . Conveyors .

Pre Treatment :

Powder Reclaim systems

Alloy Wheel Refinishing Systems

We are always looking for good used equipment customers awaiting

Please Note : We also manufacture and Install New Powder Coating systems