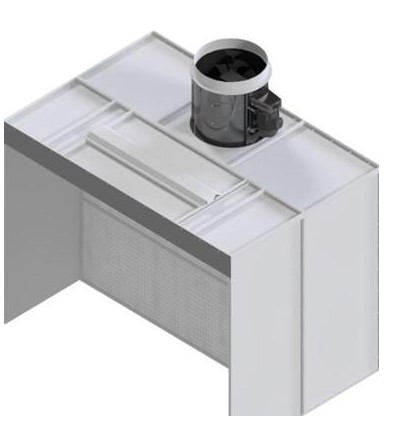

DRY FILTER SPRAY BOOTH SPECIFICATION – DFB3000

Dry filter booth floor footprint 3080mm x 2040mm deep x 2290mm high (fan height is an

addional 600mm)

- The BDA fan or fans have been rated to provide a nominal average airflow of 0.7m/s through the filters

- Dry filter booth internal working dimensions- 3000mm wide x 1000mm dep x2250mm high

- Fan or fans motor size would be 1 x 3kw / 3 rase / 41w /50hz/non atex rated

- Dry filter booths are constructed from 1.2mm galvanised steel

- BDA fan will be discharged vertically from the spray booth

- BDA fan noise levels estimated between 80-95db

- Controls — 1x dol starter to suit motor size

- BDA fan diameter or diameters 1 x 710mm

- Lighting -1 x 1500 twin battern light

Measurements & Fan specifications are based on a 3 meter wide booth as shown in illustration.

A wide range of sizes available and specified to suit Extraction on size

Dry Filter Spray Booth

Are you looking for a solution to enhance your powder coating process? Our Powder Coating Dry Filter Spray Booth is the answer!

Our state-of-the-art dry filter spray booth is designed to capture and filter overspray, ensuring a clean and controlled environment for your coating process. With our booth, you can achieve a high-quality finish while maintaining a safe and healthy working environment for your operators.

Featuring a robust exhaust fan and efficient powder collection system with specialized filters, our dry filter spray booth effectively captures and collects excess powder particles, preventing them from escaping into the surrounding environment. This means less waste, less cleanup, and reduced environmental impact.

Our filters are made of high-quality materials that are compatible with the powder coating process, and they are easy to clean or replace, ensuring consistent performance and longevity. Plus, our booth is designed for ease of use and maintenance, saving you time and effort. Here’s how it works:

Spray area:

The spray area is where the powder coating process takes place. It usually consists of a dry filter spray booth or enclosure that is designed to contain the overspray and prevent it from escaping into the surrounding environment.

Exhaust fan:

The booth is equipped with an exhaust fan that creates negative air pressure inside the booth. This helps to draw in fresh air and direct the overspray towards the filters.

Powder collection system:

As the overspray is drawn towards the exhaust fan, it passes through a powder collection system. This system typically consists of a series of filters, such as dry filters or cartridge filters, which are designed to capture and collect the powder particles.

Filters:

The filters in the powder collection system are designed to efficiently capture the powder particles while allowing clean air to pass through. The filters are usually made of materials that are compatible with the powder coating process, and they need to be periodically cleaned or replaced to maintain their effectiveness.

Investing in our Powder Coating Dry Filter Spray Booth means investing in the quality and efficiency of your powder coating process. Our solution will help you achieve a flawless finish, minimize waste, and create a safer working environment for your team.

Don’t compromise on quality and safety. Contact us today to learn more about how our Powder Coating Dry Filter Spray Booth can benefit your business!

WANTED NOW

Second hand Powder coating equipment

Second Hand Powder coating ovens

Complete Used Powder coating systems

Ovens. Booths . Conveyors .

Pre Treatment :

Powder Reclaim systems

Alloy Wheel Refinishing Systems

We are always looking for good used equipment customers awaiting

Please Note : We also manufacture and Install New Powder Coating systems