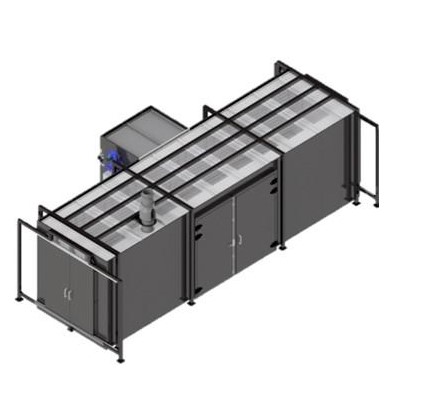

DRY OFF TUNNEL OVEN

EXTERNAL DIMENSIONS

- 3,000 MM LENGTH

- 3,500 MM WIDTH

- 2,900 MM HEIGHT

ACCESS

- ENTRY – 750 MM WIDE X 750 MM HIGH (NOM)

- EXIT – 750 MM WIDE X 750 MM HIGH (NOM)

RECIRCULATION FAN

- QUANTITY: 1 OFF

- TYPE: DIRECT DRIVEN PLUG

- VOLUME: 8,700 MVHR

- MOTOR: 4 KW

BLEED FAN

- QUANTITY: 1 OFF

- TYPE: HIGH TEMPERATURE BIFURCATED FAN VOLUME: 870 MVHR (10% BLEED)

- MOTOR: 0.55KW

AIR SEAL FAN

- QUANTITY: 2 OFF

- TYPE: CENTRIFUGAL FAN

- MOTOR: 1.1KW

HEATER

- QUANTITY: 1 OFF

- TYPE: DIRECT GAS FIRED

- FUEL: NATURAL GAS

- OPERATION: HI-LOW

- RATING: 120 KW

MAX OPERATING TEMPERATURE 100 °C

ELECTRICS: 415 V / 3 PHASE / 50 HZ

DRY OFF TUNNEL OVEN – DESCRIPTION

AIR. SEALS

- THE ENTRY OF THE DRY OFF TUNNEL OVEN WOULD BE CLOSE SILHOUETTED TO THE MAXIMUM WORKLOAD AND WOULD INCLUDE HEAT SPILLAGE CONTROL BY MEANS OF A RECIRCULATING FAN-POWERED SYSTEM.

- THE AIR SEAL INCLUDES DIRECTIONAL DAMPER BLADES TO ALLOW A SMALL OUTFLOW AT THE BOTTOM OF THE SILHOUETTE TO COUNTERACT THE NATURAL TENDENCY FOR AN INRUSH OF COLD AIR AT THE BOTTOM OF THE SILHOUETTE.

BLEED FAN

- 10% OF THE RECIRCULATED AIR IS EXHAUSTED TO ATMOSPHERE TO REMOVE ANY RESIDUAL SOLVENTS, WHICH MAY ACCUMULATE AND CAUSE AN EXPLOSION. THIS CAN OCCUR WITH POWDER PAINT AS WELL AS WET PAINT. WE FIT AN ADDITIONAL BIFURCATED FAN TO EXHAUST THIS VOLUME OF AIR.

- THE BLEED DUCT IS TO ATMOSPHERE AND COMPRISES A MANUAL DAMPER AND DISCHARGE AT HIGH LEVEL. DISCHARGE THROUGH EXISTING ROOF PENETRATION IF POSSIBLE.

CONTROL PANEL

- A SINGLE CONTROL PANEL WILL CONTROL ALL THE ELECTRICAL FUNCTIONS OF THE DUALCON SYSTEM AND CONTROL ALL THE TEMPERATURES THROUGH PLC ANALOGUE INPUTS AND OUTPUTS TO THE BURNERS AND TEMPERATURE PROBES. THIS WOULD THEN BE CONTROLLED VIA A SCREENED PANEL ON THE DOOR WHERE THE SYSTEM CAN BE MONITORED AND START AND STOP THE SYSTEM. THERE WOULD BE A MINIMUM OF THREE PAGES CONTROLLING EACH AREA OF THE INSTALLATION.

- THE DRY OFF TUNNEL OVEN OPERATING SYSTEM IS AS FOLLOWS:

- ON PRESSING THE START BUTTON THE PURGE CYCLE WILL START. IN THIS CYCLE THE RECIRCULATION FANS AND BLEED FAN WILL RUN FOR A VARIABLE TIME (NORMALLY APPROXIMATELY 2 MINUTES). THE PURGE CYCLE WARNING LIGHTS WILL BE ILLUMINATED AT THIS TIME. THE REQUIRED TEMPERATURE SHOULD BE SET DURING THIS PERIOD.

- AT THE END OF THE PURGE CYCLE THE PURGE CYCLE LIGHT WILL EXTINGUISH AND THE BURNERS WILL START THE FIRING CYCLE. THE BURNERS WILL FIRE UNTIL SET POINT TEMPERATURE IS REACHED AND THEN TURN DOWN TO A LOW HOLDING FLAME.

- THE EMERGENCY STOP BUTTON SHOULD BE USED ONLY IN EMERGENCIES AND NOT FOR STOPPING THE DRY OFF TUNNEL OVEN NORMALLY.

WANTED NOW

Second hand Powder coating equipment

Second Hand Powder coating ovens

Complete Used Powder coating systems

Ovens. Booths . Conveyors .

Pre Treatment :

Powder Reclaim systems

Alloy Wheel Refinishing Systems

We are always looking for good used equipment customers awaiting

Please Note : We also manufacture and Install New Powder Coating systems